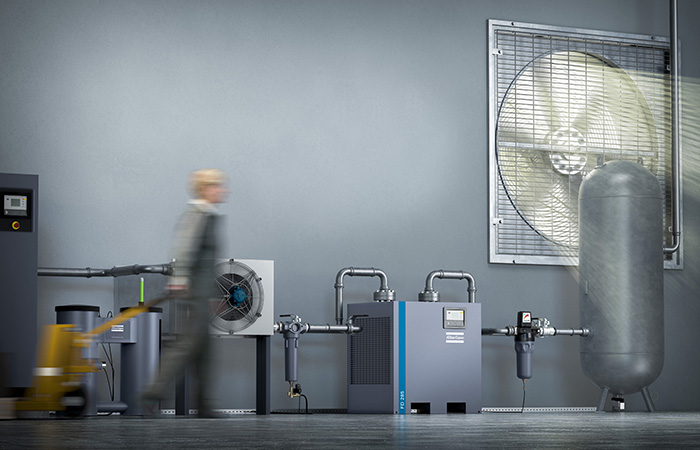

Why Compressor Condensate Management is Important

Condensate, or the liquid formed from compressed air, contains more than just water. It is a combination of hydrocarbons, and other potential airborne contaminates broken down into tiny particles suspended in water. This emulsification is not acceptable to discharge into a municipal sewage system without first being treated. Properties of the liquid can change depending on the environment and the manufacturing process.

Emulsification

Management of compressed air condensate may be as simple as installing a filter that separates the oil and other contaminants from water or at least to an acceptable level before being discharged. Some facilities use oil water separators North Carolina to treat their condensate, while other facilities that produce large quantities of liquid may choose to use a wastewater treatment process.

Concentration

The emulsified liquid can have a high or low pH value depending on outdoor conditions. The piping, plastic fittings, tubing, and valves can be impacted … Read more